Mildly interesting

-

Can you freeze a hamster solid then bring it back it to life using microwaves?

Link to video -

@George-K How often is that performed on a horse's hoof? I bet it stinks something awful when they apply the heated shoe.

What happens to wild horses hooves over time?

@mark said in Mildly interesting:

@George-K How often is that performed on a horse's hoof? I bet it stinks something awful when they apply the heated shoe.

We had Simon seen by the farrier about every six weeks. It's another of those horse-owning expenses that add up, as @jodi can verify!

YEs, it stinks like a MoFo - nothing like it in the world, LOL.

What happens to wild horses hooves over time?

Domesticated horses live a very different life. They spend a lot of time in a stall where the ground is soft, or covered with hay. In the wild, the hooves are constantly being worn down by rocky and rough terrain.

Simon had arthritis problems and the farrier suggested that he go barefoot so that the natural "spring" and give of the hoof would be less stressful on his joints. It seemed to make a difference.

Being a farrier is hard, physical work. You have to have a furnace for heating the shoe, an anvil for pounding the shoe into shape to fit that horse's hoof, etc.

Go to about 5:25.

Link to videoAnd then, there are some horses that can be "less than cooperative."

It's also very much precision work. A poorly-fitting shoe can really make a horse miserable - just like a poorly fitting shoe in a human.

-

@mark said in Mildly interesting:

@George-K How often is that performed on a horse's hoof? I bet it stinks something awful when they apply the heated shoe.

We had Simon seen by the farrier about every six weeks. It's another of those horse-owning expenses that add up, as @jodi can verify!

YEs, it stinks like a MoFo - nothing like it in the world, LOL.

What happens to wild horses hooves over time?

Domesticated horses live a very different life. They spend a lot of time in a stall where the ground is soft, or covered with hay. In the wild, the hooves are constantly being worn down by rocky and rough terrain.

Simon had arthritis problems and the farrier suggested that he go barefoot so that the natural "spring" and give of the hoof would be less stressful on his joints. It seemed to make a difference.

Being a farrier is hard, physical work. You have to have a furnace for heating the shoe, an anvil for pounding the shoe into shape to fit that horse's hoof, etc.

Go to about 5:25.

Link to videoAnd then, there are some horses that can be "less than cooperative."

It's also very much precision work. A poorly-fitting shoe can really make a horse miserable - just like a poorly fitting shoe in a human.

-

@George-K Just thinking, who decided to try this first? Then to know what to cut, how deep etc. Ugh. I feel bad for the first horses that went through that.

-

@George-K Just thinking, who decided to try this first? Then to know what to cut, how deep etc. Ugh. I feel bad for the first horses that went through that.

-

@mark said in Mildly interesting:

who decided to try this first

Probably the same guy who looked at a cow, saw the udder and said, "Let's squeeze that and drink what comes out, m'kay?"

-

From https://www.rainforest-alliance.org/species/blue-morpho-butterfly/ The blue morpho butterfly’s wings are bright blue, edged with black. The blue morpho is among the largest butterflies in the world, with wings spanning from five to eight inches. Their vivid, iridescent blue coloring is a result of the microscopic scales on the backs of their wings, which reflect light.

-

Can you freeze a hamster solid then bring it back it to life using microwaves?

Link to video@mark said in Mildly interesting:

Can you freeze a hamster solid then bring it back it to life using microwaves?

Link to videoI am not sure that I want to watch this video… If it doesn’t have a happy ending, I don’t… And if it DOES have a happy ending, I still don’t think I want to know, LOL.

-

From https://www.rainforest-alliance.org/species/blue-morpho-butterfly/ The blue morpho butterfly’s wings are bright blue, edged with black. The blue morpho is among the largest butterflies in the world, with wings spanning from five to eight inches. Their vivid, iridescent blue coloring is a result of the microscopic scales on the backs of their wings, which reflect light.

@Catseye3 said in Mildly interesting:

From https://www.rainforest-alliance.org/species/blue-morpho-butterfly/ The blue morpho butterfly’s wings are bright blue, edged with black. The blue morpho is among the largest butterflies in the world, with wings spanning from five to eight inches. Their vivid, iridescent blue coloring is a result of the microscopic scales on the backs of their wings, which reflect light.

Where’s Cano?

@Aqua-Letifer should get that one, at least…

-

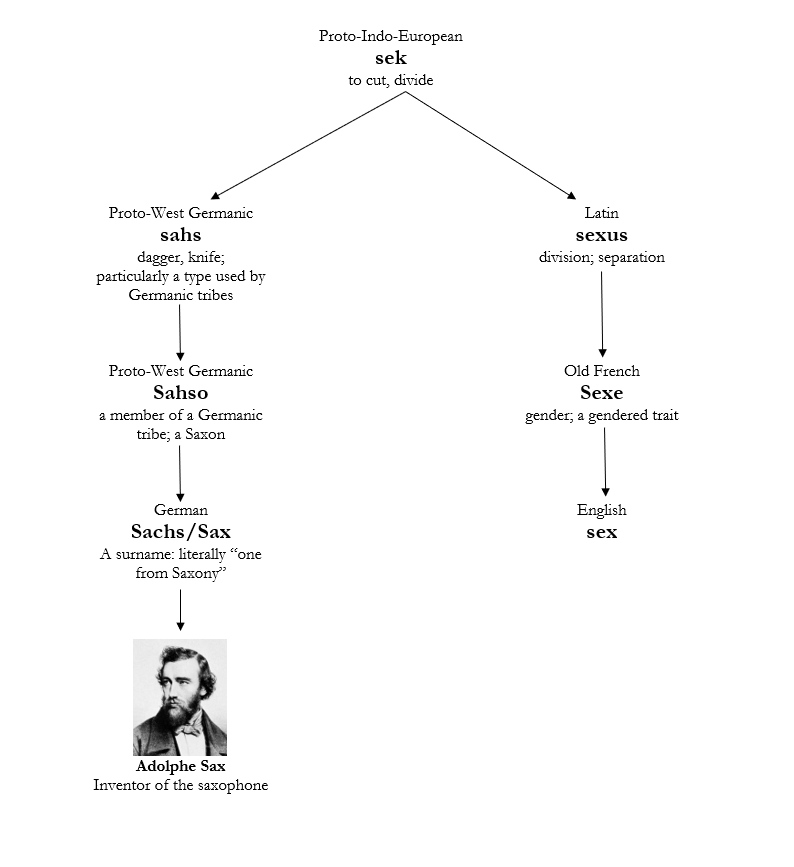

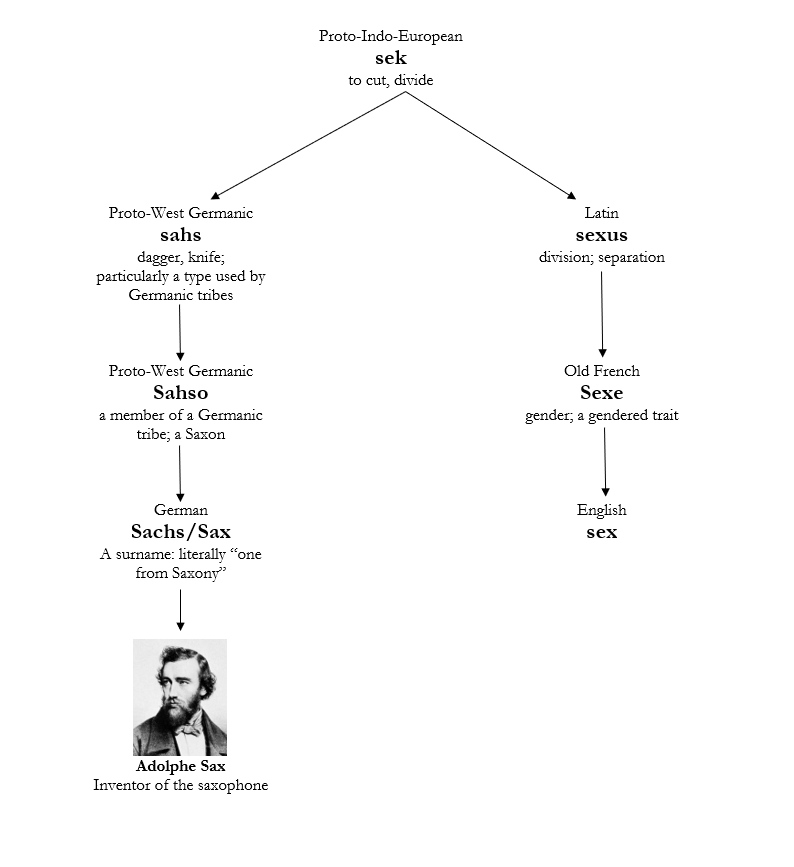

For @Doctor-Phibes

-

For @Doctor-Phibes

@George-K so the instrument is a sex machine! I knew it!

-

So there I was, eating Cheetos out of the bag and otherwise expanding my mind through valuable Internet insights when it occurred to me to wonder how Cheetos are made. Here's what Wired said:

"Making Cheetos: It Ain't Easy Being Cheesy.

"Gritty cornmeal stored in a silo is pumped about 100 yards through a pneumatic tube into a Cheetos manufacturing plant. (Frito-Lay has 14 fried-Cheeto plants in 11 states.) The cornmeal then enters a giant hopper , where it awaits its rapid transformation into one of America's most beloved snacks.

"Gobs of cornmeal are fed into an extruder , which rubs the meal between two metal plates. The friction melts the starch in the corn and causes the moisture to heat up. When it passes its boiling point, the meal "pops," creating the Cheetos shape. The craggy bits are then spit out of the extruder, flying 3 feet at high velocity before hitting a safety cage and dropping onto a conveyor belt.

"The Cheetos move through a piping-hot pan of vegetable oil, much like an amusement-park log flume. The oil not only imparts a fatty flavor but also fries the snack's moisture content down below 2 percent—a key to crunchiness. Once suitably cooked, the pieces go back on a conveyor belt

"The puffs hit a tumble drum, where strategically located nozzles spray a mixture of oil and powdered cheese onto the Cheetos from all sides. The cheese, which Frito-Lay buys pre-spiced in 50-pound sacks (the company won't say from whom), looks like the stuff used in boxed macaroni-and-cheese products.

The pieces are dropped onto a last conveyor belt, where any remaining moisture steams off as they cool to room temperature. The finished Cheetos are then moved toward the packaging area, to be bagged, boxed, and shipped.

"Every half hour, an in-house lab analyzes the chemical composition of samples pulled from the cooking line to verify that the Cheetos have the right density and nutritional content. Then, every four hours, a four-person panel convenes to inspect and taste the snacks, comparing them to perfect reference Cheetos sent from Frito-Lay headquarters."

There you have it. From now through the rest of your life, whenever somebody asks you if you know how Cheetos are made, there you'll be, reddy as Freddy with the whole story.

NNTTM.

For moar plus pix: https://www.wired.com/2010/05/process-cheetos/#:~:text=Gobs of cornmeal are fed,%2C" creating the Cheetos shape.